Hardware Development

// Application-specific electronics design for system integration.

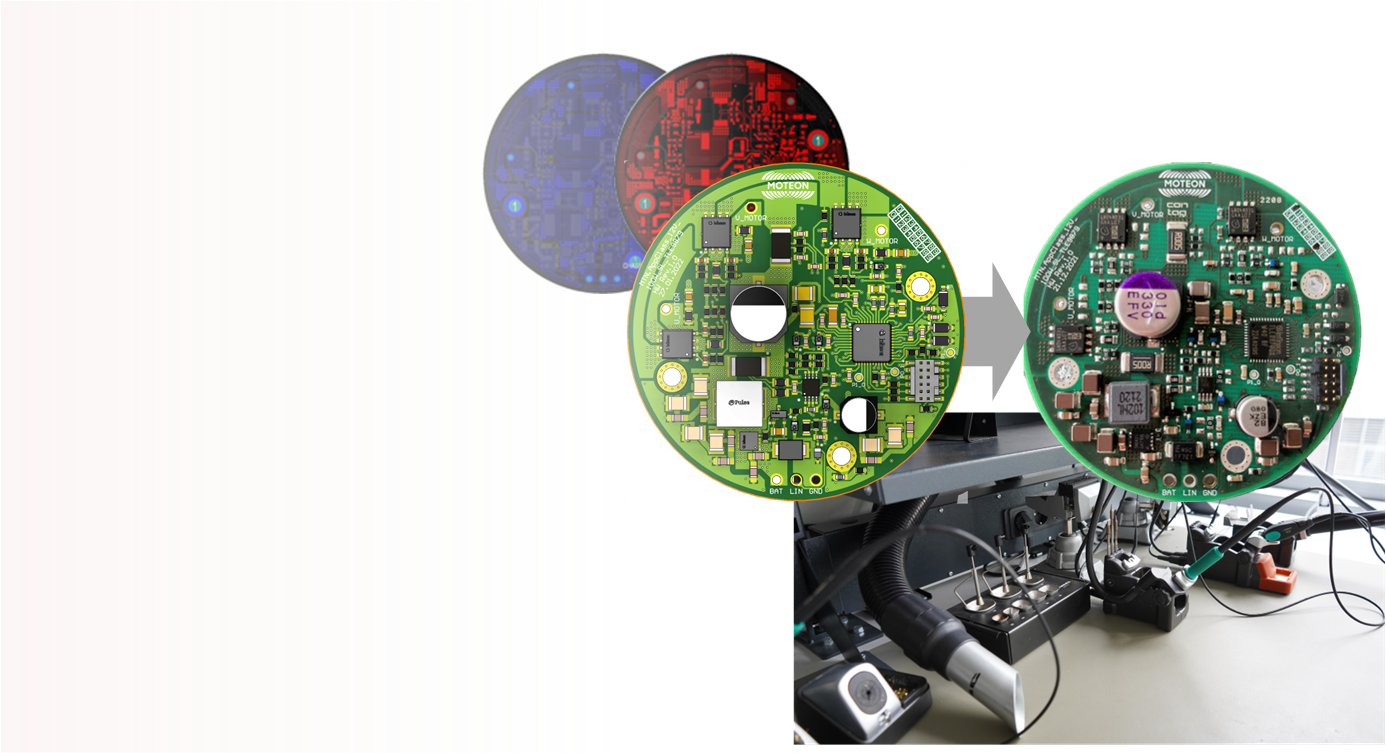

Electronics Hardware Development

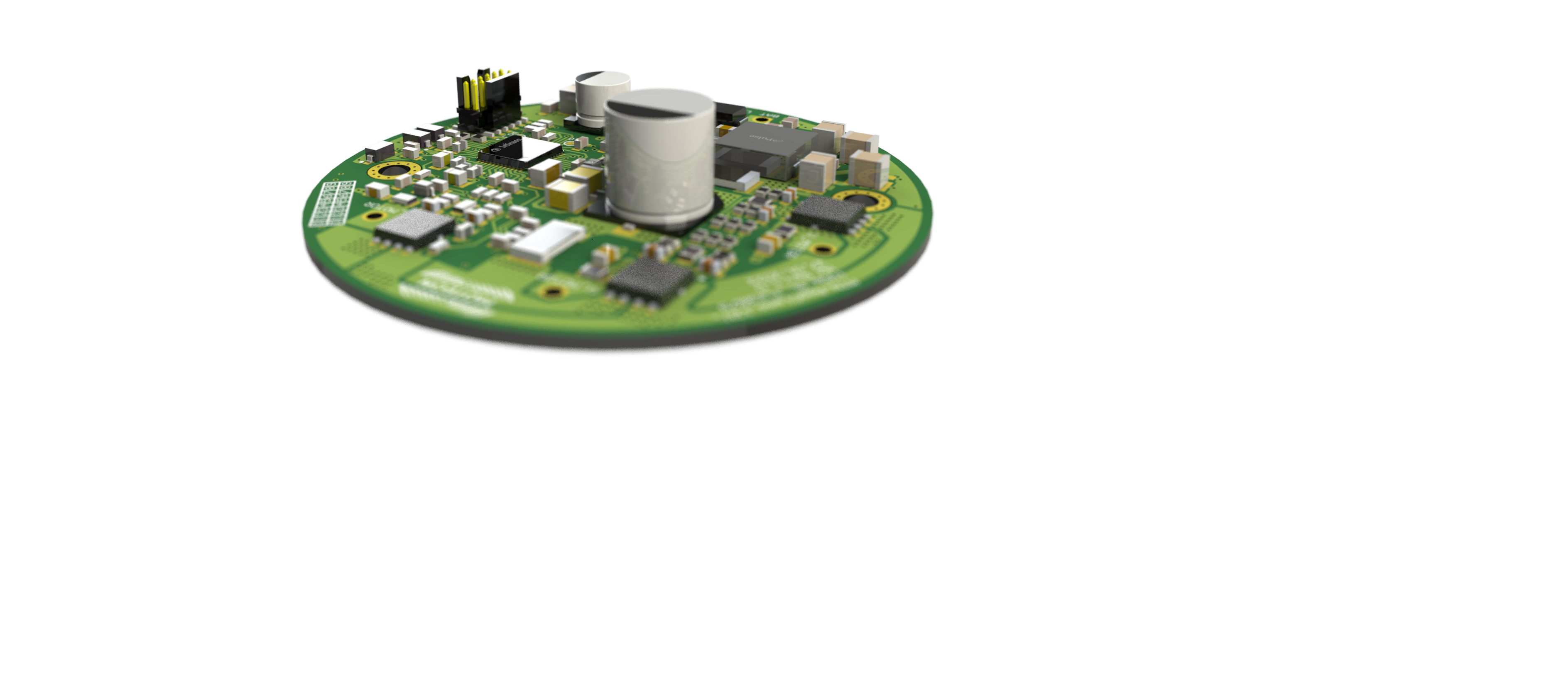

The electronics hardware development contains the design of application-specific electronics on functional sample level and the manufacturing of prototypes for target system integration. For this purpose, the ECAD is supported by MCAD integration options, which results in a spatial and functional design tailored to the target application.

Your benefits at a glance

Basis for price indication for series production

Identifying and addressing design issues reduces development costs

Design data set as starting point for industrialization

Early integration of the electronics in the target system

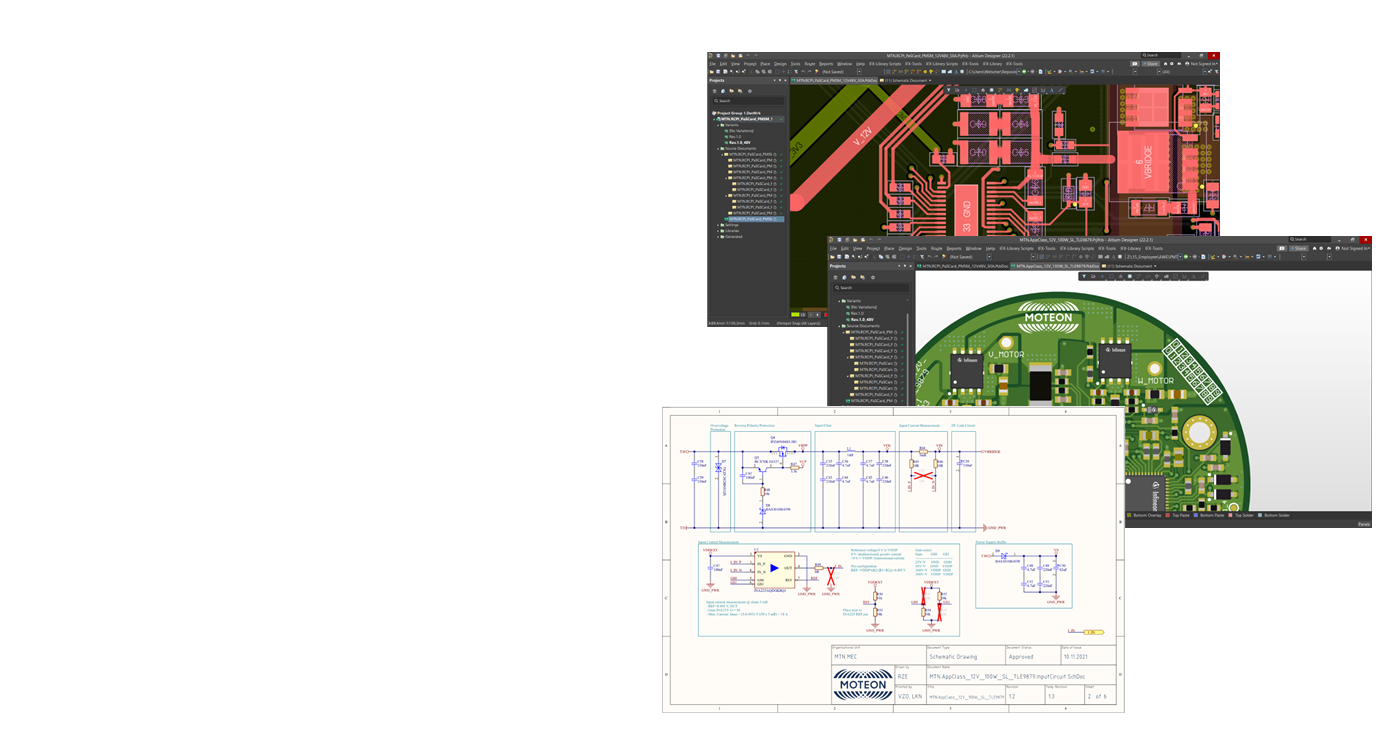

Schematic and PCB Design

- Schematic design tailored to the requirements of the application and the components used

- Component placement study to fit construction space and mechanical interface requirements realized by ECAD and MCAD collaboration

- PCB layout design considering signal quality, EMC guidelines, efficiency and heat dissipation

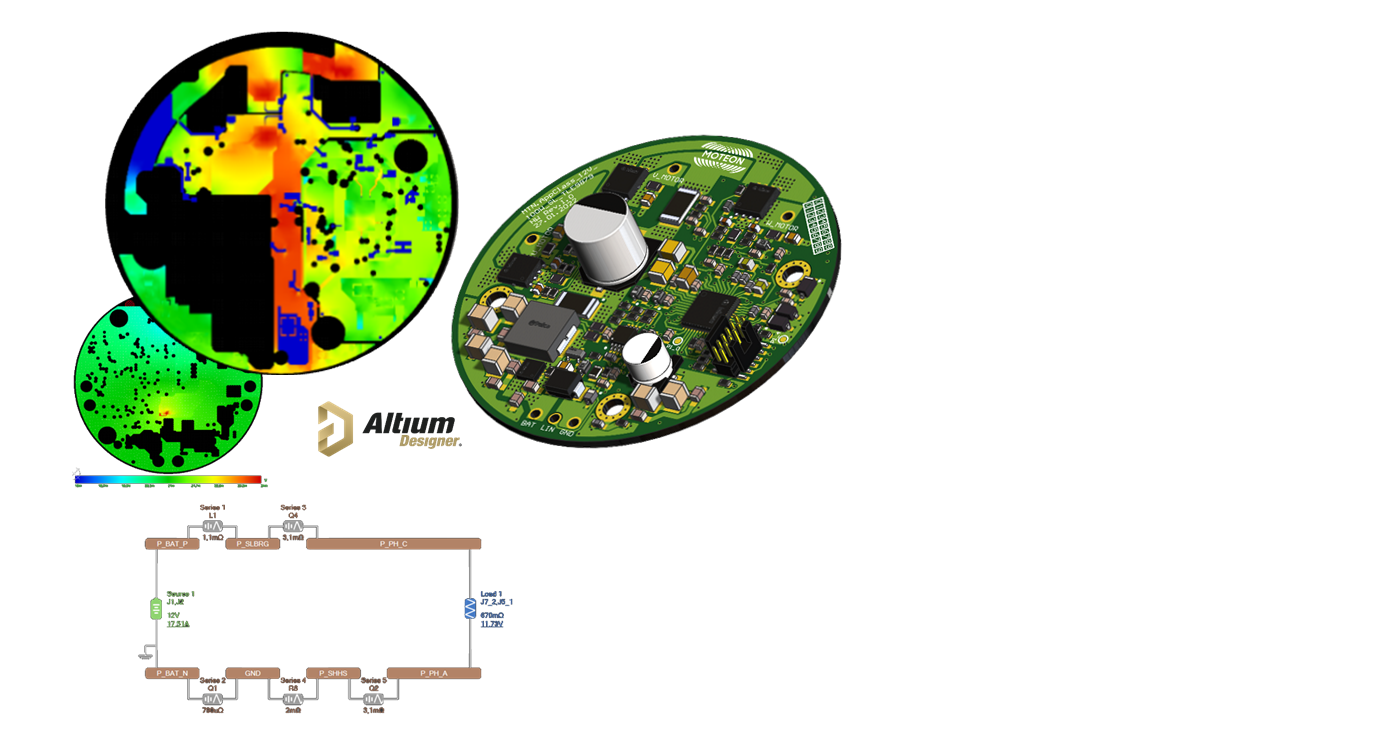

Simulative hardware design validation

- Power integrity analysis using the PDN Analyzer to increase the PCB performance

- Simulating of voltage drops and current density

- Determination of the copper losses in the power path for consideration in a thermal CFD analysis

Prototyping and manufacturing

- Sample production in cooperation with well-known or customer-specific EMS

- Provision of all relevant production data (Schematic, BOM, Drill and Gerber data)

- Basic rework options on the electronics in the in-house soldering laboratory

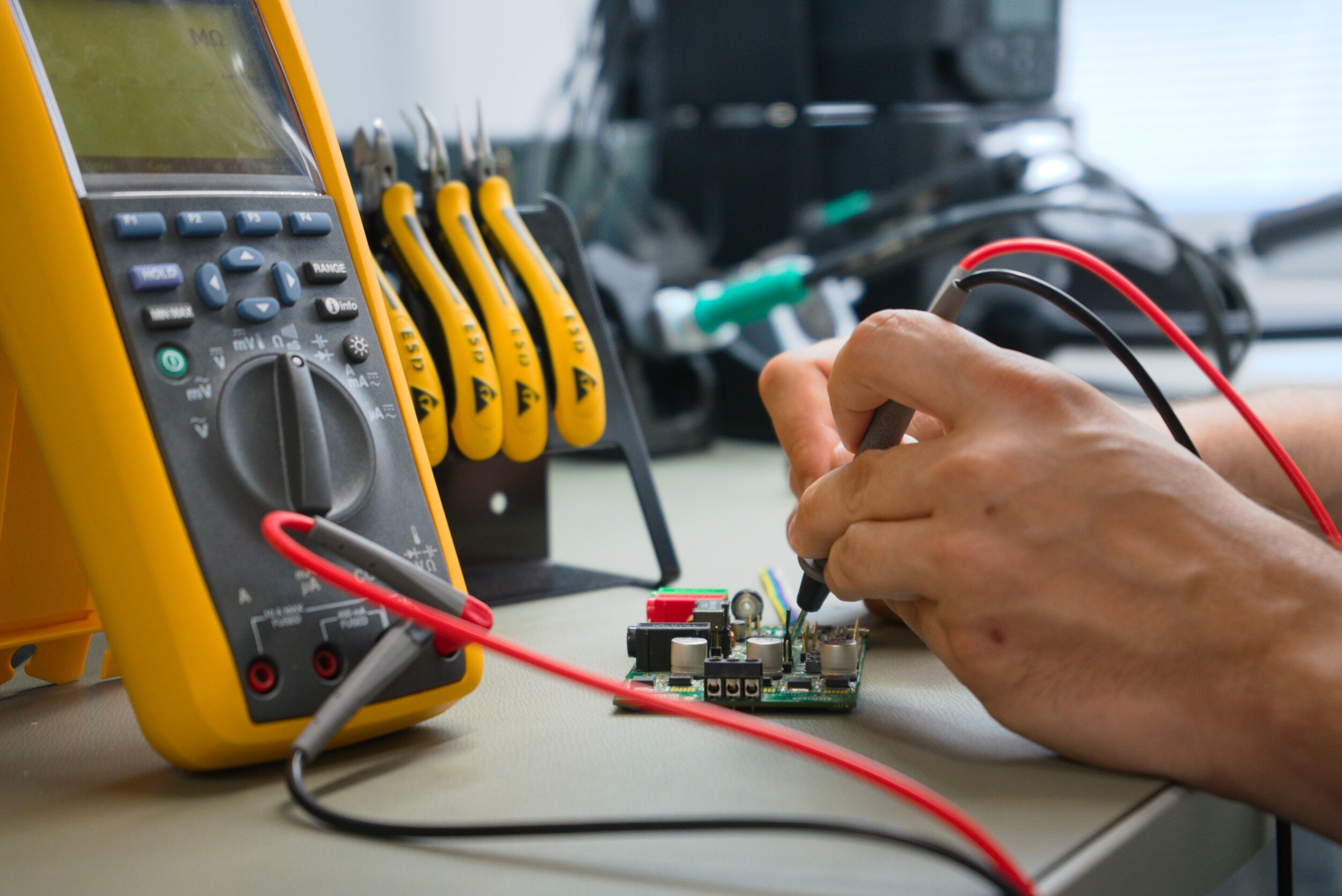

Basic electronics inspection

- 100% incoming inspection of electronics samples

- Basic manual optical check regarding PCB population quantity and quality

- Components according to BOM and assembly data, component placement and proper solder connection

- Basic electrical test regarding expected values (current consumption, voltage levels, reverse polarity functions)