Mobile Motor Test Bench (mMTB)

// The compact way of testing motors and electronics.

Mobile Motor Test Bench

In the development of motor applications, flexible adaptations to the control and measurement options are essential due to dynamic changes in conditions. The Mobile Motor Test Bench (mMTB) is a compact test bench designed to help developers debug and verify their software and hardware for embedded motor control applications in a standardized and functionally safe environment. Thanks to its mechanical modules, the mMTB can be quickly set up without compromising its high safety standards, even in workplace settings.

Some facts about the Mobile MTB

Rapid testing of motor control algorithms

Compliance with safety standards

Real time data tracing

Compact & robust design

Your benefits at a glance

Mobile Motor Test Bench

The mMTB offers the advantage of testing a wide variety of motor applications within an office setup. This allows a rapid development process, enhancing the product life cycle.

With its mechanical modules and diverse load profiles, the mMTB allows for quick setup and development of custom motor applications across various motor types. The mMTB has a power supply capable of voltages up to 60 VDC and currents up to 50 A, suitable for test objects up to 1 kW. Additionally, it provides up to 768 W of continuous power for the load motor.

The integration of the TraceBox into an embedded system expands the mMTB´s functions. This includes time synchronization via EtherCAT as well as the identification and analysis of software bugs and system behavior.

By using the mMTB at the developer's workstation, the developer has the opportunity to receive permanent feedback about their modifications and improvements, which accelerates the development process. Thanks to its compact and robust design, the mMTB conforms to the required safety standards and upgrades the development workspace to the next level.

Flexible data management ensures and speeds up result-oriented analysis. The acquisition and processing of controller-internal data takes place time-synchronously and with real-time capability.

One mMTB for various use cases

- Developing and testing variety of motor applications

- Using one test motor with one electronic control unit

- Simple adjustment due to standardized mechanical elements

- Individual tools with integrated data tracing & debugging (e.g. MOTIX™ Embedded Software)

The mMTB in an office environment

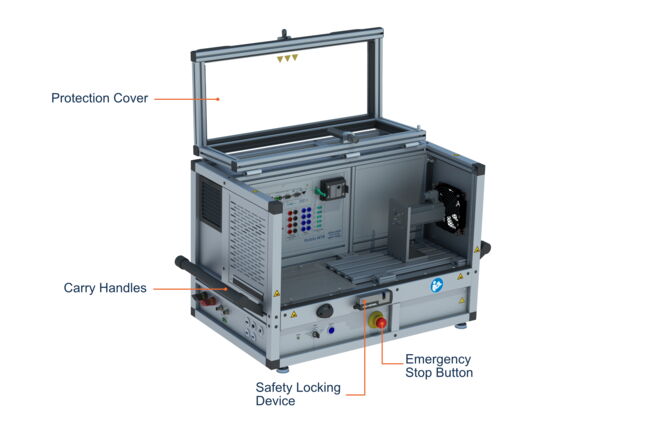

- Monitoring of the protection cover

- Foot pedal to stop in case of panic reaction during adjustment

- Selector switch for safe use of the operating modes

- Electrical contact protection

- Comfortable transport due to carry handles

- Safety labelling for accident prevention and activity orientation

mMTB with more than one function

- Wide range of functionality of control and measurement options

- Measurement options for determining specific motor control parameters (e.g. voltage, currents, temperature etc.)

- Load motor to emulate the load of the target mechatronic system

- Flexible data management ensuring focus-specific result analysis

- Possibility to test the communication interface

- Time synchronization via EtherCAT

Mobile Motor Test Bench

The mMTB is connected with the PC and combines the TraceBox, load motor (LM) and integrated power supply (IPS) in a safe development environment to test the device under test (DUT). This latter includes the motor and the electronic control unit (ECU). The mMTB is attached to an external load power supply (LPS) as well.

Parametrics

Dimension with handles |

926 x 543 x 529 mm |

Dimension without handles |

760 x 543 x 480 mm |

Supply voltage Mobile MTB |

230 VAC (Max. 16 A) |

Supply voltage device under test |

Max. 60 VDC (Max. 50 A/ Max. 1000 W) |

Shaft speed |

Max. 10.000 rpm |

Operating temperature |

15 ... 40 °C |

Acoustic pressure level |

Max. 80 dB (A) on heavy load |

Documents

1. Download the User Manual from the Infineon Developer Center

2. Read the user manual carefully the safety instructions

3. Follow the instructions in the user manual for set-up, installation, operation, maintenance and service.

4. Implement your tests via the Python example (can be downloaded in IDC) or a professional testing tool which allow the ASAM XIL interface standard (e.g. tracetronic ecu.test, Vector CANoe)